Lean Design & Engineering Support

As part of our broader service offerings, OpEx Innovative Designs offers comprehensive Lean Design & Engineering Support, tailored to optimize your manufacturing processes and enhance product quality. By applying Lean Six Sigma principles, we help you streamline design, engineering, and production workflows to drive efficiency and deliver high-impact solutions.

We leverage the full power of Dassault Systèmes’ 3DEXPERIENCE platform, integrating advanced tools like SOLIDWORKS for design, ENOVIA for lifecycle management, SIMULIA for virtual testing, and DELMIA for production planning. This advanced technology enables seamless collaboration, near real-time feedback, and cost-effective solutions, from concept to production and beyond.

‣ Services:

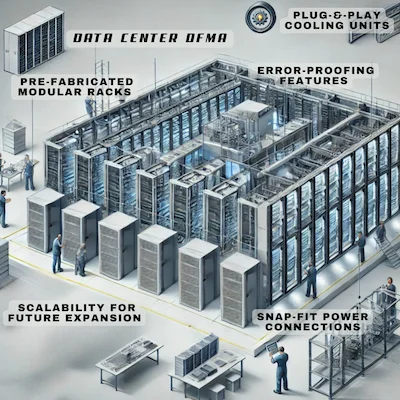

Design for Manufacturing and Assembly (DFMA)

We simplify and optimize product designs by eliminating waste, reducing complexity, and minimizing part counts while maximizing quality, reliability, and cost savings.

Poka-Yoke (Mistake-Proofing) Strategies

We integrate innovative mistake-proofing mechanisms (Poka-Yoke) into designs to prevent errors, reduce defects, and improve product quality and reliability throughout manufacturing and assembly.

Custom Equipment and Tooling Development

We design and integrate custom tools and equipment to overcome production challenges, enhance efficiency, and improve product quality. Our tailored solutions address tight constraints while seamlessly integrating with your existing infrastructure and optimizing production line performance.

Engineering Drafting Support

We provide detailed drafting support from concept to final design, ensuring accuracy and precision at every stage of development. Whether creating new designs or refining existing ones, we leverage SOLIDWORKS and the 3DEXPERIENCE platform to enhance collaboration and deliver seamless, end-to-end digital continuity—from initial concepts to manufacturing documentation and beyond.

Simulate and Test Designs

We leverage advanced simulations using SIMULIA, integrated within the 3DEXPERIENCE platform, to optimize product designs for real-world performance. This approach reduces the need for costly prototypes, minimizes manufacturing errors, improves durability, and accelerates development.

Custom Labeling and Identification Designs

We design customized labeling solutions, including QR-coded nameplates and phenolic tags, to improve traceability, streamline operations, and elevate branding. These advanced designs integrate QR codes for instant access to manuals, safety information, and parts data, enabling seamless digital integration and smoother service and upgrade processes.

Product Family Management

We standardize parts and streamline production workflows to enhance consistency, reduce redundancies, and improve overall manufacturing efficiency.