Process Optimization & Efficiency Enhancement

At OpEx Innovative Designs, Process Optimization & Efficiency Enhancement is the cornerstone of our services, integrating Lean Six Sigma principles and Dassault Systèmes technology into every solution we offer.

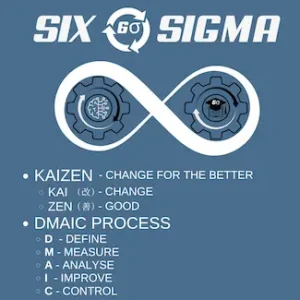

Our Lean Process Optimization services transform your operations by driving efficiency, boosting productivity, and reducing waste. By integrating Dassault’s 3DEXPERIENCE platform—including SOLIDWORKS for design, DELMIA for production planning, and ENOVIA for lifecycle management—we create seamless, data-driven solutions. Combining these tools with Lean Six Sigma methodologies like DMAIC (Define, Measure, Analyze, Improve, Control) and Kaizen exercises, we simulate, analyze, and refine your processes before implementation, ensuring changes yield lasting improvements.

‣ Services:

Production Flow Optimization

We optimize production flow by streamlining workflows, designing pull-based production systems aligned with real demand, and enhancing throughput by eliminating bottlenecks, optimizing facility layouts, and utilizing DELMIA for simulations and analysis.

Facility and Material Storage Layouts

Our team develops scalable and efficient facility layouts for material handling and storage, providing storage solutions that improve material movement, minimize excess inventory, and allow space for future expansion.

Production Line Development

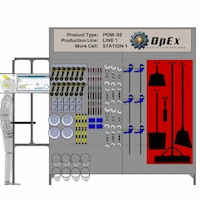

We design scalable production lines, standardizing work cells while incorporating visual controls that are integrated within our KANBAN and 5S solutions, to ensure consistency and maximize productivity while minimizing waste.

Tailored Tool and Material Management Systems

We design custom KANBAN and 5S workstations to organize required tools and materials precisely where and when they are needed, utilizing visual organization with tool signage and shadow board drawings to optimize tool layout and reduce search time.

Custom Production and Ergonomic Tools

We develop tailored production tools and ergonomic workspaces that drive efficiency, reduce downtime, and minimize waste. Our comprehensive solutions enhance safety, lessen physical strain, boost employee satisfaction, and lower costs associated with workplace injuries and inefficiencies—all while streamlining operations and reducing waste.

Capital Expenditure (CapEx) Budgeting and ROI Analysis

We develop CapEx budgets and perform ROI analysis for your projects, providing you with the necessary data required to make informed decisions on facility improvements and equipment investments.

Comprehensive Process Optimization (Lean Six Sigma methodologies)

Our tailored Lean Six Sigma methodologies, utilizing DMAIC and Kaizen principles, optimize workflows, enhance efficiency, and reduce waste in manufacturing operations. We provide the expertise, planning, and support needed to transform your facility, allowing for sustainable growth and long-term success.